Polyester Composite Strap with PET Strap Difference

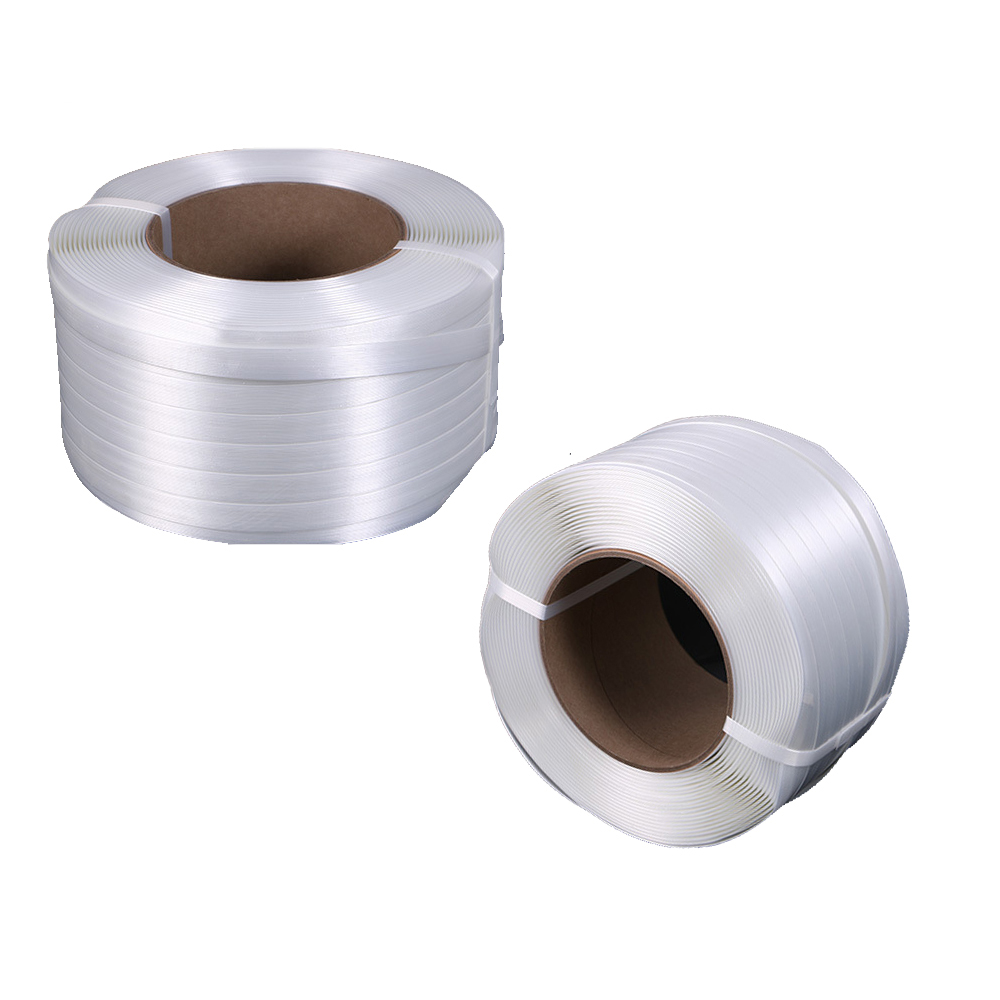

Polyester Composite Strap is a widely used material in packaging due to its high strength, flexibility, and resistance to damage. It is often made up of a polyester core, surrounded by a woven polyester fabric, and then coated with polyvinylidene chloride (PVDC) or ethylene-vinyl acetate (EVA). This construction provides a strong, weather-resistant strap that can be used for a variety of applications.

On the other hand, Composite Strap is a popular choice for high-performance applications due to its high tensile strength, low coefficient of friction, and good resistance to chemicals and UV rays. It is often used in the packaging of heavy items, such as machinery and building materials, where secure and stable bundling is required.

The main difference between polyester composite strap and PET strap lies in their construction and resulting properties. While Poly Cord Strapping is made up of multiple layers and materials, polyester strap is a single material. This difference results in polyester strap having a higher tensile strength but lower elongation at break compared to composite strapping.

Polyester composite strap, on the other hand, has a lower tensile strength but higher elongation at break due to its layered construction. It also provides better protection against UV rays and chemicals. Additionally, composite strapping is generally more expensive than polyester strapping due to its complex manufacturing process.

In conclusion, both polyester composite strap and PET strap have their unique advantages and uses.Polyester Composite Strap is best suited for applications where high elongation and protection from UV rays and chemicals are required, while polyester strapping is best for high-performance applications where tensile strength is crucial.

BSTSTRAP

No.30 building, Wuxing High-tech Venture Park

Huzhou City, Zhejiang Province,China

Whatsapp:+86 136 6574 4776

Monday to Saturday 9 am to 5 pm

hailey@bststrap.com

Send us your enquiry anytime!