Hot Melt Strapping: The Innovative Polyester Textile Strap

Hot melt strapping is a revolutionary strapping solution that has been gaining significant popularity in various industries. It is essentially a polyester textile strap where polyester yarns are glued together using a hot melt adhesive. This innovative technology offers numerous advantages over traditional strapping methods, making it an ideal choice for securing and bundling goods.

The process of manufacturing hot melt strapping involves weaving polyester yarns together and then applying a hot melt adhesive to bond the yarns. This unique combination of materials and manufacturing process results in a durable, strong, and flexible strap that can withstand the rigors of transportation and storage.

One of the primary advantages of hot melt strapping is its high strength-to-weight ratio. This means that it can provide a secure hold on goods while being significantly lighter than steel or other metal strapping alternatives. As a result, it reduces transportation costs and improves overall efficiency.

Another significant benefit of hot melt strapping is its resistance to moisture and corrosion. Unlike metal strapping, which can rust and degrade over time, polyester strapping remains unaffected by moisture and can maintain its strength and integrity for extended periods. This makes it an ideal choice for industries that require strapping solutions that can withstand harsh environments.

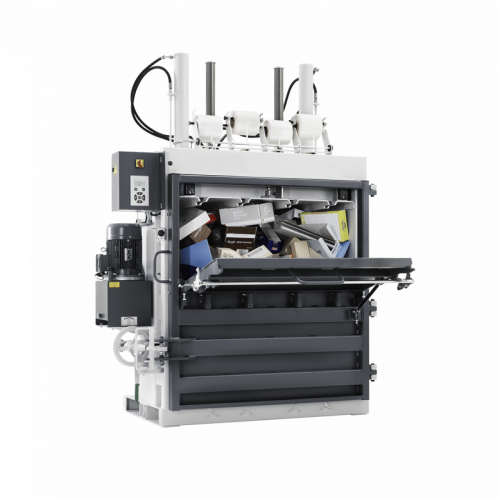

Hot melt strapping is also known for its ease of use. It can be applied quickly and efficiently using a variety of tools, including hand-held strapping tools, semi-automatic, and fully-automatic machines. This makes it an ideal choice for businesses seeking to streamline their packaging and strapping processes.

In addition to its practical advantages, hot melt strapping is also environmentally friendly. It is made from recyclable materials and can be easily disposed of without causing harm to the environment. This makes it a more sustainable choice than traditional metal strapping, which can contribute to waste and pollution.

Despite its many advantages, hot melt strapping does have some limitations. For example, it may not be suitable for heavy-duty applications that require extreme tensile strength. However, for most industries and applications, hot melt strapping offers a reliable, cost-effective, and sustainable strapping solution.

In conclusion, hot melt strapping is a versatile and innovative strapping solution that offers numerous advantages over traditional methods. Its high strength-to-weight ratio, resistance to moisture and corrosion, ease of use, and environmental friendliness make it an ideal choice for businesses seeking a durable, reliable, and sustainable strapping solution. As hot melt strapping continues to gain popularity, it is likely to become the go-to strapping solution for a wide range of industries and applications.

BSTSTRAP

No.30 building, Wuxing High-tech Venture Park

Huzhou City, Zhejiang Province,China

Whatsapp:+86 136 6574 4776

Monday to Saturday 9 am to 5 pm

hailey@bststrap.com

Send us your enquiry anytime