Advancing Packaging Solutions: The Emergence of Hot Melt Polyester Strapping

In the dynamic field of industrial packaging, hot melt polyester strapping is carving out a niche as a leading solution for secure and efficient bundling. This innovative strapping material is gaining traction across various industries due to its impressive performance characteristics and versatility. As companies seek to enhance their packaging processes, hot melt polyester strapping is becoming a key player in the quest for strength, durability, and sustainability.

**What is Hot Melt Polyester Strapping?**

Hot melt polyester strapping is a type of packaging strap made from polyester fibers that are bonded together using a hot melt adhesive. This adhesive technology allows the strap to maintain its strength and integrity even under challenging conditions, providing a reliable solution for securing and bundling products.

Unlike traditional polypropylene or steel strapping, hot melt polyester strapping offers several distinct advantages. The use of hot melt adhesive enhances the strap’s ability to maintain tension and resist breakage, making it an excellent choice for high-stress applications. Additionally, the polyester fibers provide a combination of flexibility and durability that ensures the strap can withstand the rigors of shipping and handling.

**Key Benefits of Hot Melt Polyester Strapping**

1. **Exceptional Strength and Durability:** Hot melt polyester strapping is renowned for its high tensile strength, which makes it suitable for bundling heavy and bulky items. The strap's ability to maintain its strength even under extreme conditions ensures that packages remain secure throughout the supply chain.

2. **Superior Resistance to Environmental Factors:** One of the standout features of hot melt polyester strapping is its resistance to moisture, UV rays, and temperature fluctuations. This makes it ideal for use in various environments, including outdoor and industrial settings where traditional straps might falter.

3. **Enhanced Safety and Ease of Use:** The hot melt adhesive used in polyester strapping provides a secure bond that reduces the risk of slippage or breakage during transport. Additionally, the strap's flexibility and ease of application make it user-friendly, reducing the time and effort required for packaging operations.

4. **Reduced Maintenance and Cost-Effectiveness:** Hot melt polyester strapping's durability translates to lower maintenance costs and fewer replacements. This cost-effectiveness is particularly beneficial for businesses with high-volume packaging needs, as it helps streamline operations and reduce overall expenses.

**Applications Across Industries**

Hot melt polyester strapping is finding applications across a range of industries, thanks to its versatile performance characteristics:

1. **Logistics and Transportation:** In the logistics sector, hot melt polyester strapping is used to secure pallets and bundles of goods for transportation. Its strength and resistance to environmental factors ensure that products arrive at their destination intact and undamaged.

2. **Construction:** For the construction industry, hot melt polyester strapping is employed to bundle materials such as timber, steel, and concrete. The strap’s ability to handle heavy loads and withstand outdoor conditions makes it a valuable tool for construction projects.

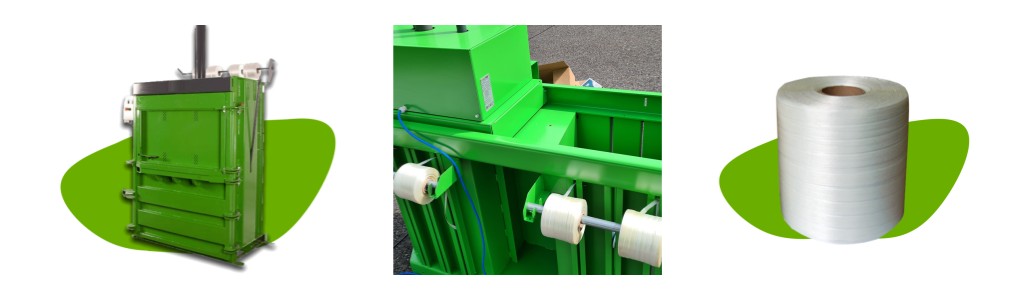

3. **Recycling:** The recycling industry benefits from hot melt polyester strapping’s ability to compress and secure bales of recyclable materials. Its durability and resistance to moisture ensure that bales remain stable during handling and processing.

**Sustainability and Future Outlook**

As sustainability becomes a growing focus, hot melt polyester strapping is also evolving to meet environmental demands. Manufacturers are exploring the use of recycled and eco-friendly materials to produce polyester strapping, aligning with global efforts to reduce plastic waste and carbon footprints.

Looking ahead, the future of hot melt polyester strapping appears promising. Advances in materials science and adhesive technologies are expected to enhance the strap’s performance and sustainability further. Additionally, the integration of smart technologies in packaging systems may drive innovations in strapping solutions, offering even greater efficiency and functionality.

**Conclusion**

Hot melt polyester strapping is revolutionizing the packaging industry with its blend of strength, durability, and environmental resistance. As businesses seek to optimize their packaging processes and embrace sustainable practices, hot melt polyester strapping represents a forward-thinking solution that addresses both performance and environmental concerns. For companies looking to enhance their packaging efficiency and reliability, investing in hot melt polyester strapping is a strategic choice that aligns with the evolving demands of the industry.